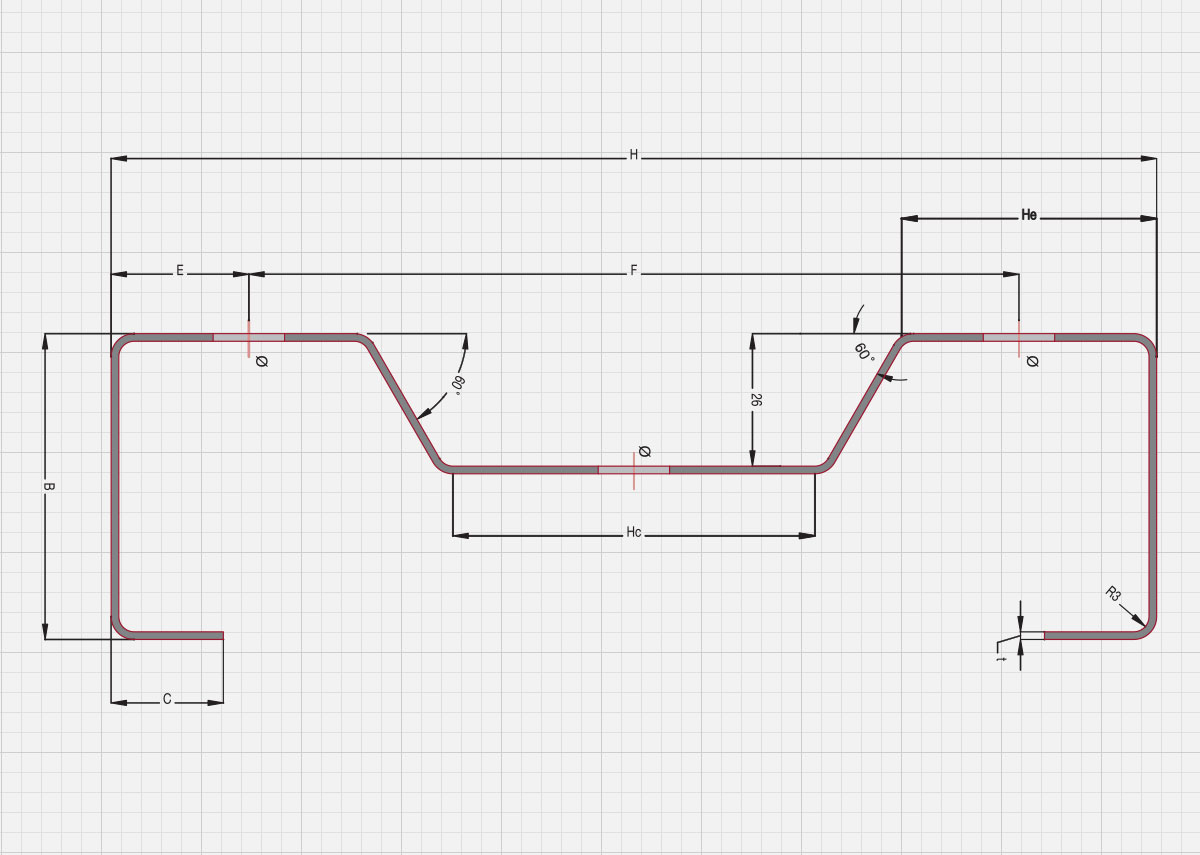

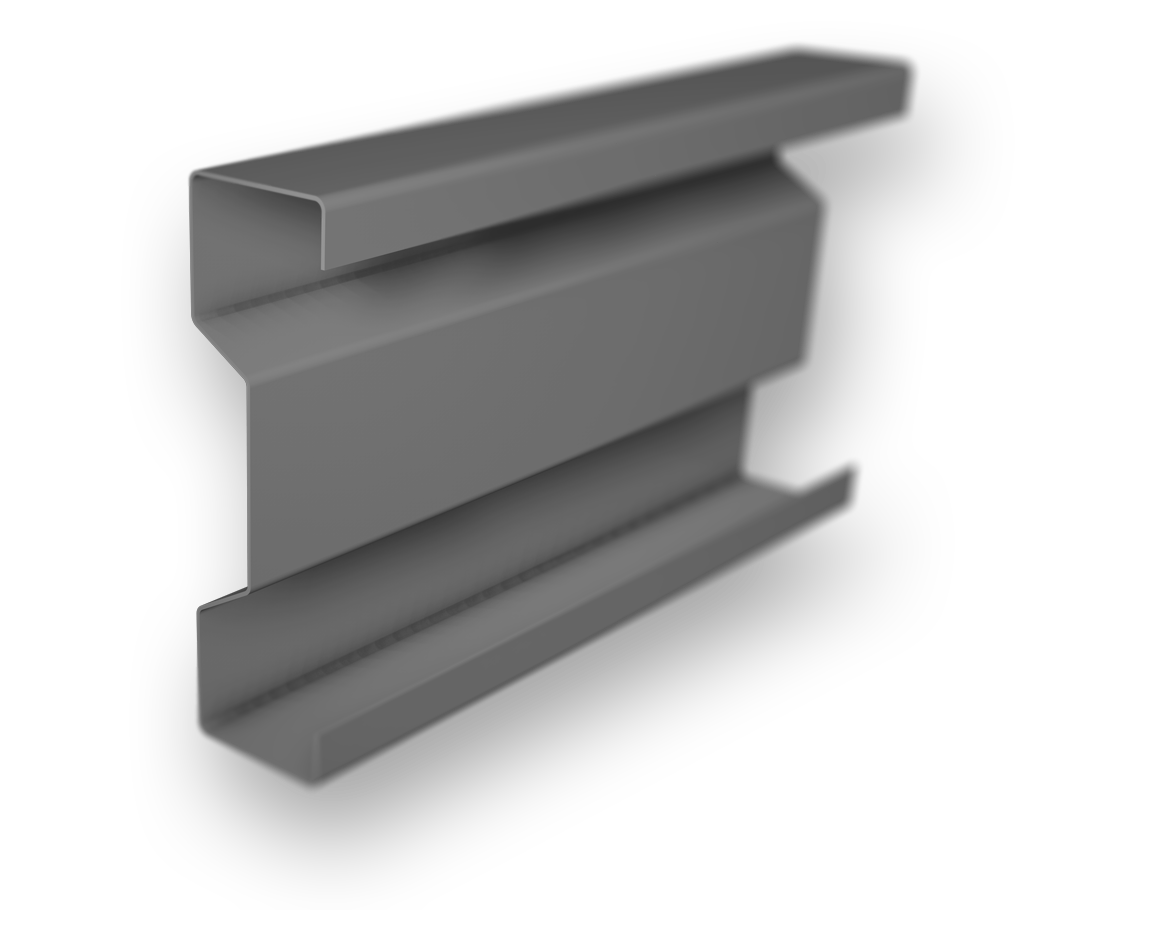

- Appropriate either for side or roof purlins.

- Suitable for decking (used for example in composite-concrete deck, steel sheet or MDF).

- Different types of configuration (one span, two spans, three or multiple continuous spans connected with "sleeve" profile).

- SIGMA profiles are available custom-cut in any transportable length and delivered in strapped bundles.

- Each profile is marked, according to the designer's drawing.

The cold form sections Σ are used as secondary steel frame structure of metal construction, decreasing its weight up to 50%, compared to the ordinary hot rolled steel sections (H-Beams, e.g. IPE, IPN etc).

The combination of the particular geometrical characteristics and the high resistance of steel (S 320) that cold formed sections hold, has as a result increased resistance in relation to their weight. For each type of cold form section the topology of bolting holes can be provided so that it is delivered ready for erection, according to the designer's drawings. Having the advantage of customization, cold form sections can be manufactured according to customer's specifications (type, length, holes). Accessories are also available, necessary for the installation of the cold formed sections on the base metal frame (e.g. connection sleeves).

Advantages

- High strength to weight ratio (load capacity).

- Decrease of the total weight of the metal base framing.

- Consistent quality. Production for hot-galvanized, high resistance steel.

- Close dimensional tolerances.

- Production according to the customers' requirements (forming progress, hole punching, final length).

- Marking based on constructional drawing for easier erection.

MARKING OF COLD FORM SECTIONS

- Cold form section product line is able to mark each profile, according to the designers' drawings (name of client, number of drawing, type of profile, length).

- The product line is easily programmed, by using NC files.

ELASTRON cold form sections are included in libraries of specialized software of metal construction design.