The thermo-insulating cold rooms and storage rooms panels CORE are composite, self-supporting structural elements, consisted of two profiled sheets bonded in an insulating rigid foam core of polyurethane (PUR) or polyisocyanurate (PIR).

They completely satisfy the European specifications that refer to the hygiene and protection of food in the areas of its production, storage and preservation.

Are conformed to the European Standard EN 14509: 2013 and are CE marked.

ECOPANEL FL is designed to meet the special needs and demands of areas for which they are destined. Are ideal for food production and processing areas, preservation and freezing areas, control atmosphere environments areas, laboratories etc.

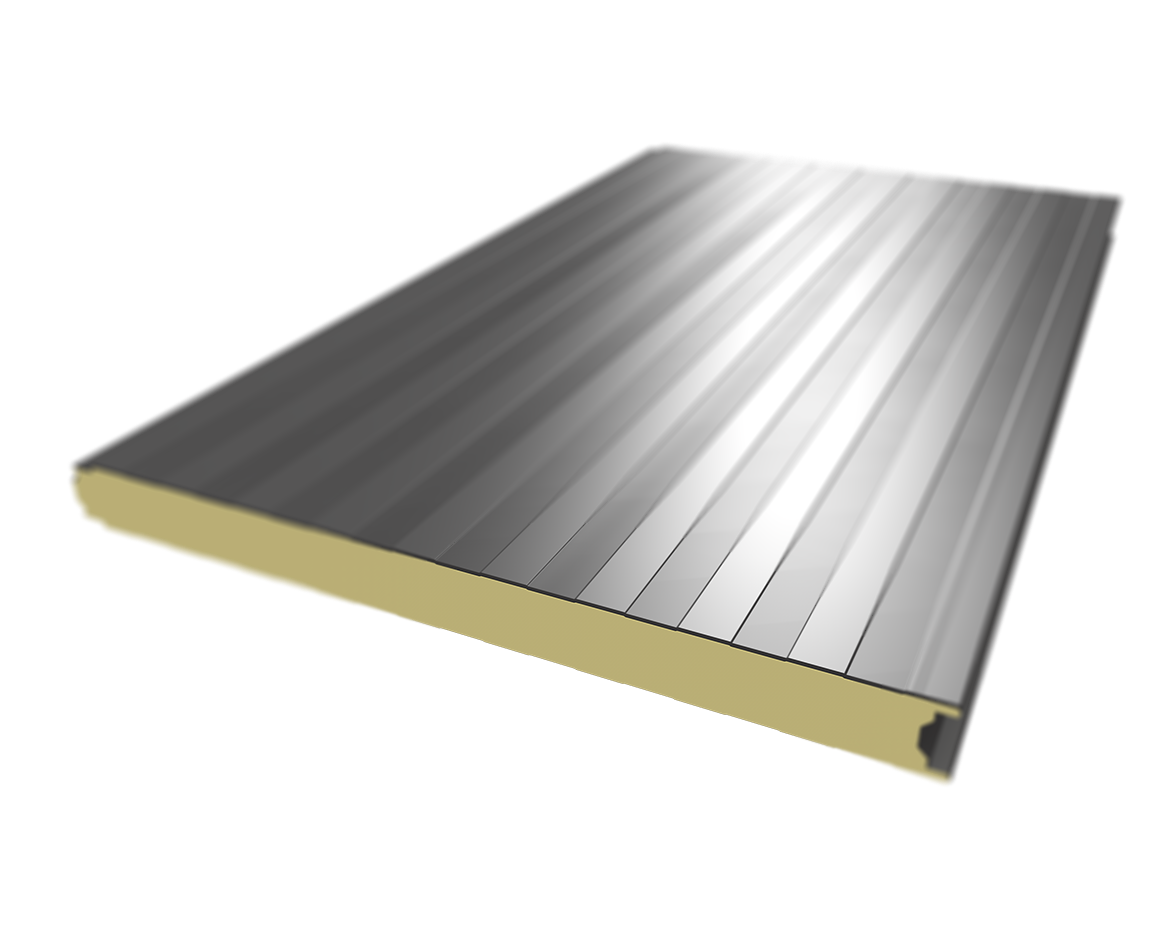

Particular attention has been given to the design of their joints as well to the characteristics of their components such as the insulating core and the steel sheets and coatings as PVC-Food-Safe. The standard both faces are slightly shaped “standard” type or flat. The standard steel sheet thickness of both faces is 0.40mm - 0.45mm. The standard top coating on both faces is Polyester 25μm in 9002 RAL scale colour or PVC-Food-Safe, white color, non-toxic and suitable for contact with food. Under request are available variable steel sheet thickness, coatings and colours, according to the specific demands of the project.

Special features

- Almost zero gap external joints suitable for highest standards of cleanliness in controlled environments.

- Special shaping internal joints for high performance of jointing sealability.

- Removable before installation paper strips in both sides of joint for a better foam contact.

- Polyurethane foam core CFC Free & HCFC Free. Harmless to the environment and safest for the ozone layer.

- Steel sheet shape slightly corrugated or flat in both sides, suitable for food processing rooms.

| Panel Type |

Outer sheet thickness

(mm) |

Inner sheet thickness

(mm) |

D

(mm) |

Weight

(kg/m 2) |

Heat transmission

coefficient U (W/m 2K) |

Max length

(m) |

|

|---|---|---|---|---|---|---|---|

| FL 80 | 0.45 | 0.45 | 80 | 8.99 | 0.15 | 16.0 | 16.0 |

| FL 100 | 0.45 | 0.45 | 100 | 10.89 | 0.21 | 16.0 | |

| FL 120 | 0.45 | 0.45 | 120 | 11.65 | 0.18 | 16.0 | |

| FL 150 | 0.45 | 0.45 | 150 | 12.79 | 0.14 | 16.0 | |

| FL 180 | 0.45 | 0.45 | 180 | 13.93 | 0.12 | 16.0 |

Thermal conductivity "λ" = 0,02 W/m*K

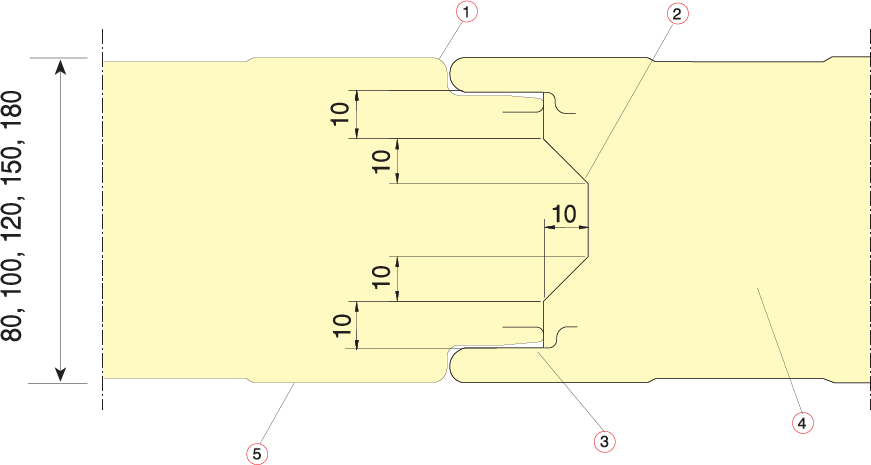

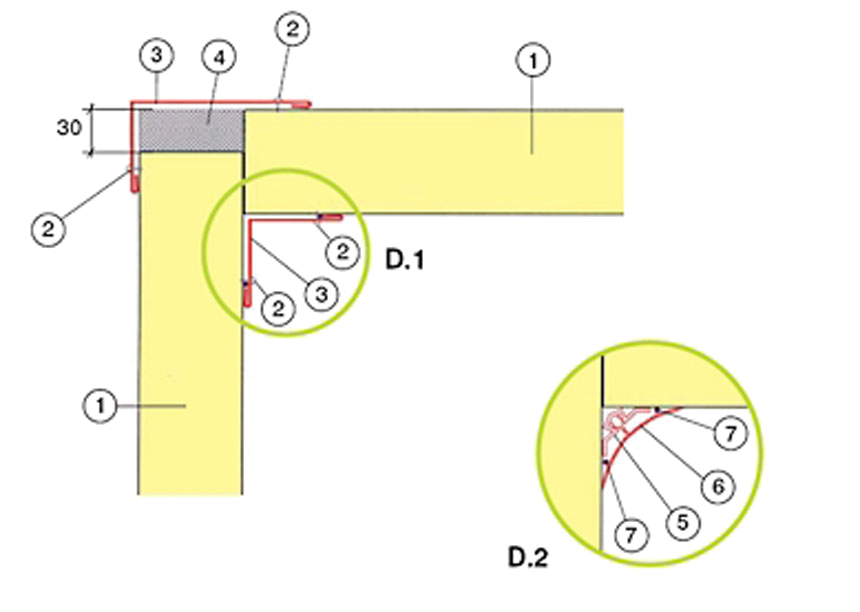

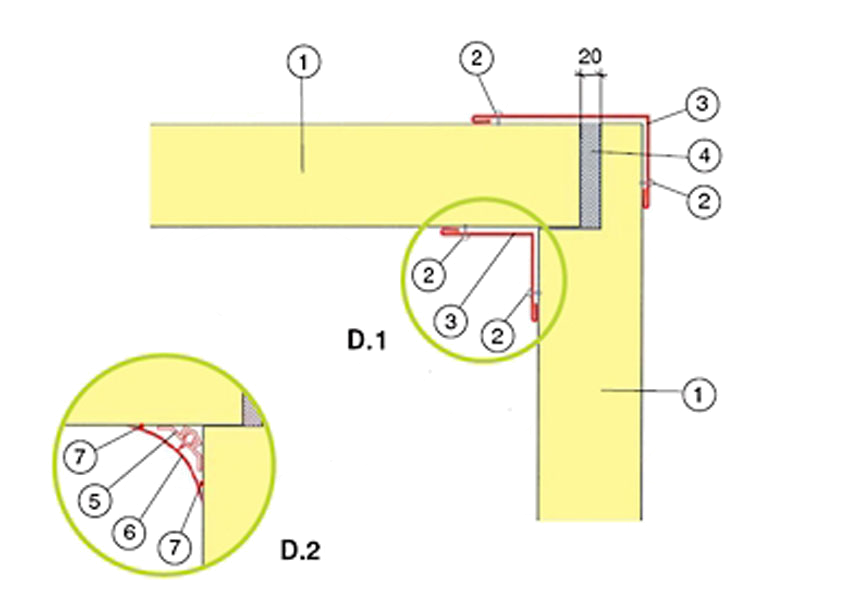

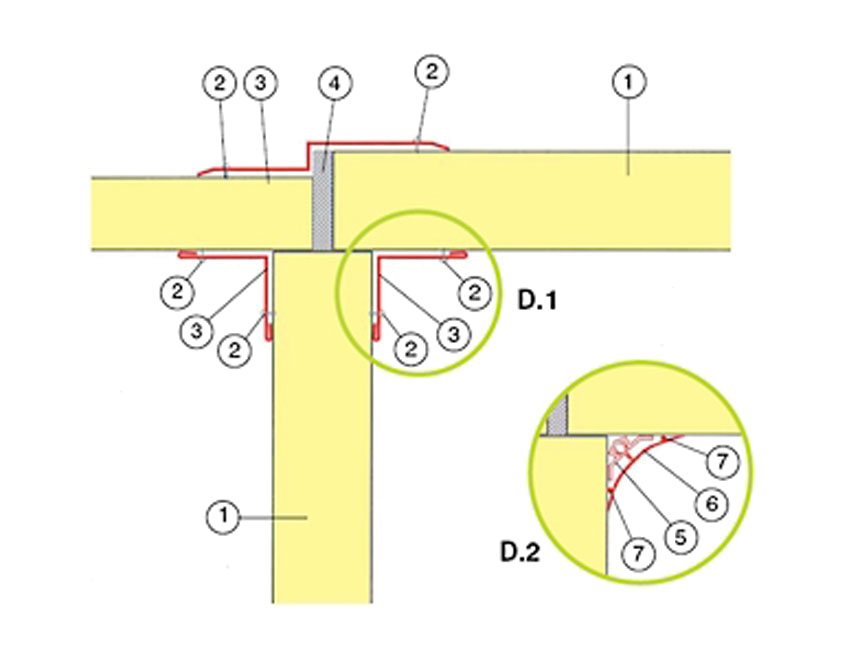

Construction details

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Polyurethane injection

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

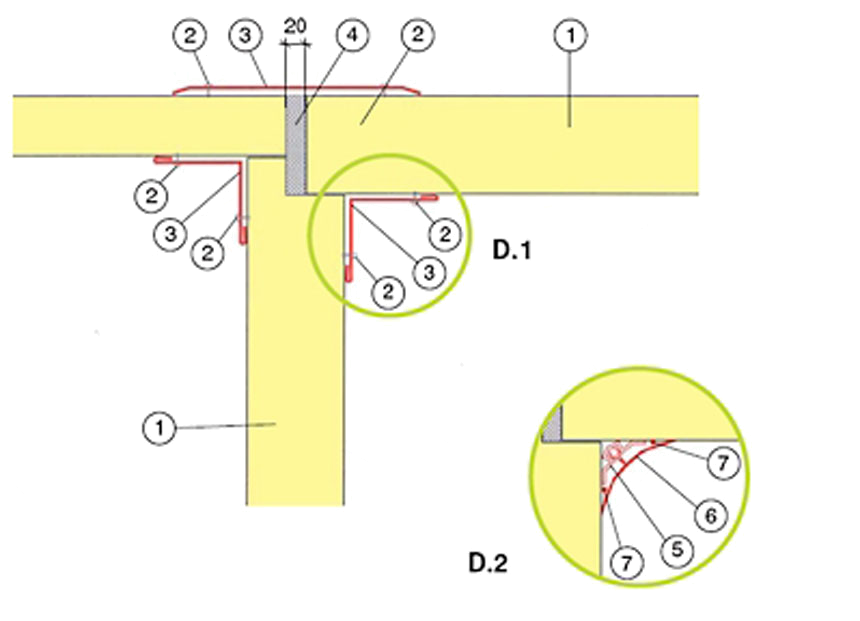

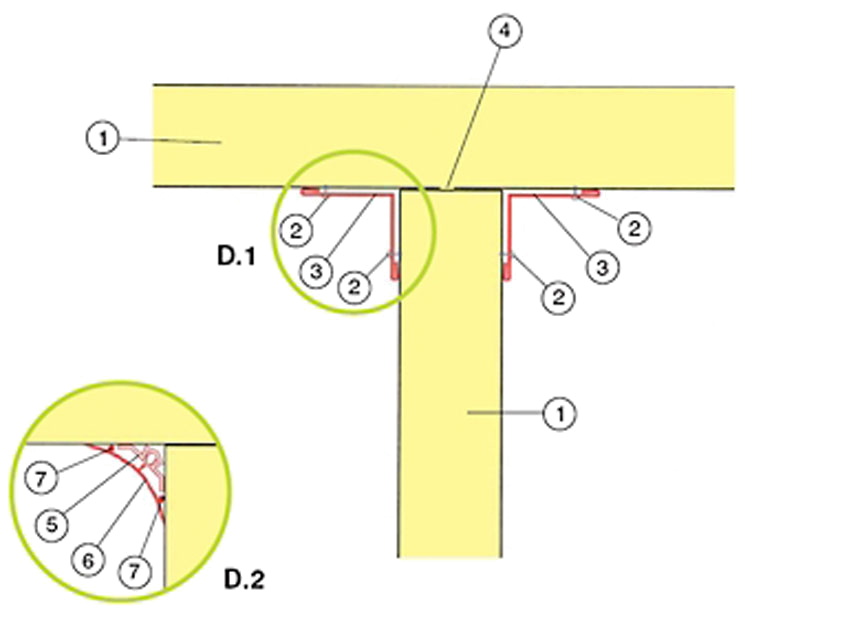

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Polyurethane injection

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

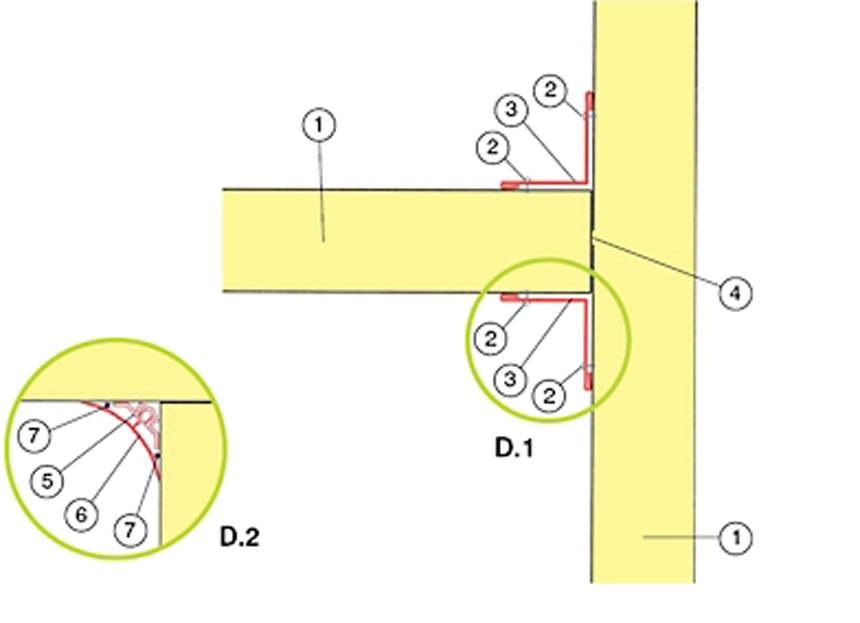

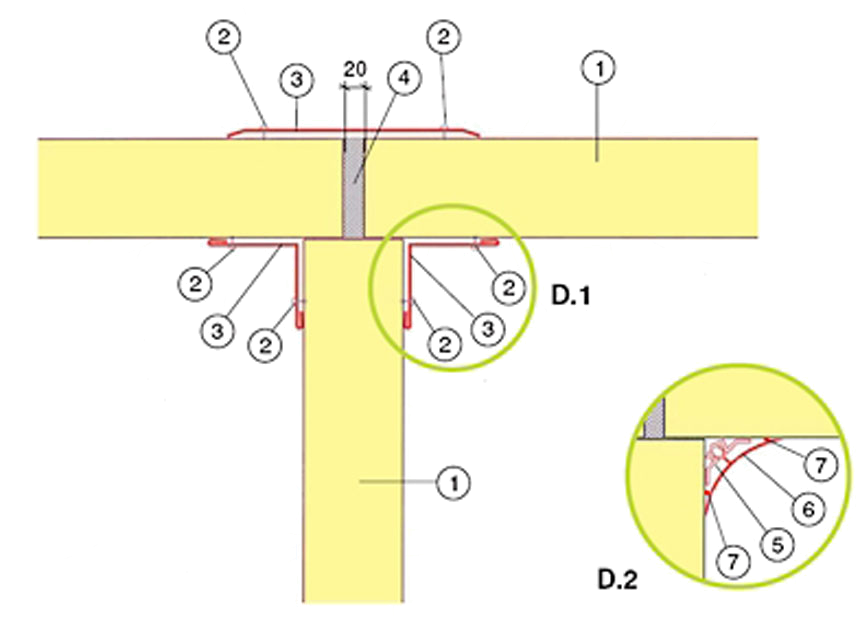

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Thermal break (Steel sheet cutting)

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

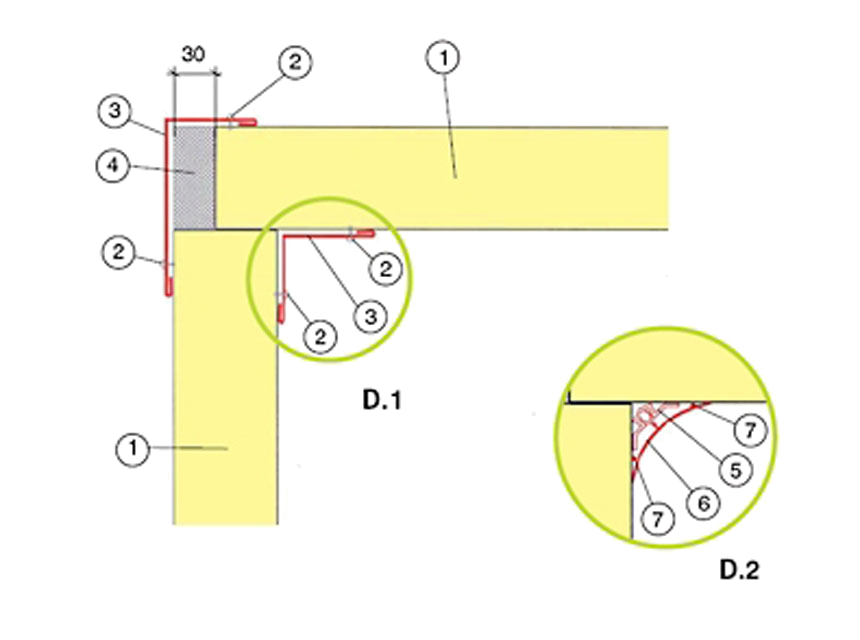

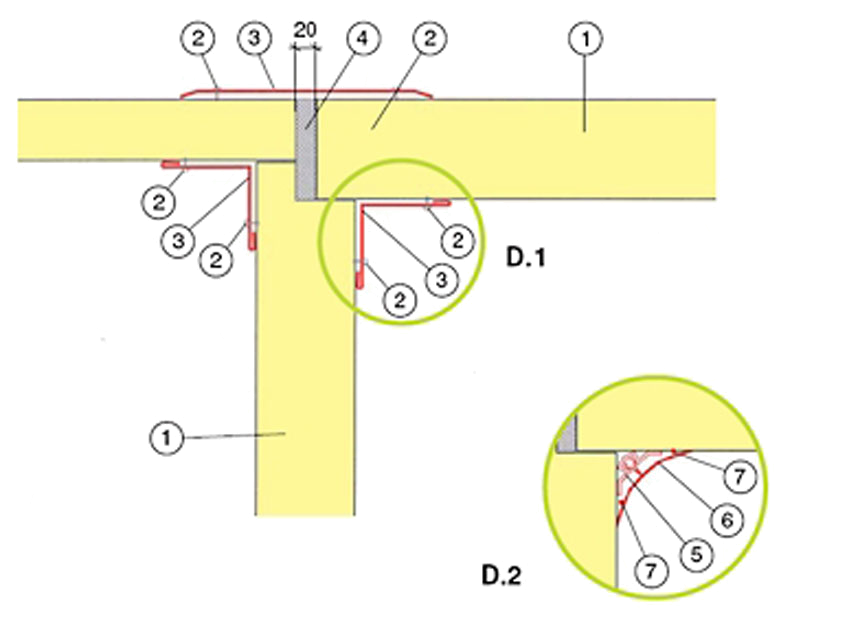

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Polyurethane injection

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Polyurethane injection

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Thermal break (Steel sheet cutting)

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Polyurethane injection

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Polyurethane injection

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

- 1. ECOPANEL FL

- 2. Rivet

- 3. Coated steel flashing

- 4. Polyurethane injection

- 5. Angle support

- 6. Sanitary angle profile

- 7. Silicone sealant

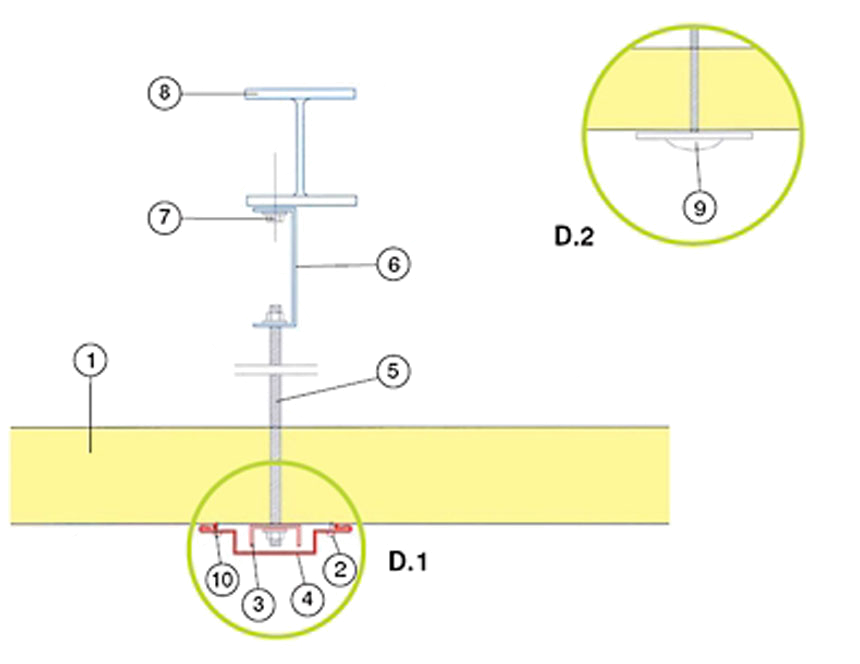

- 1. ECOPANEL FL

- 2. Rivet

- 3. Supporting galvanized U profile

- 4. Omega coated steel flashing

- 5. Teflon screw rod

- 6. Galvanized U profile

- 7. Screw

- 8. Truss

- 9. Teflon washered screw cap

- 10. Silicone sealant

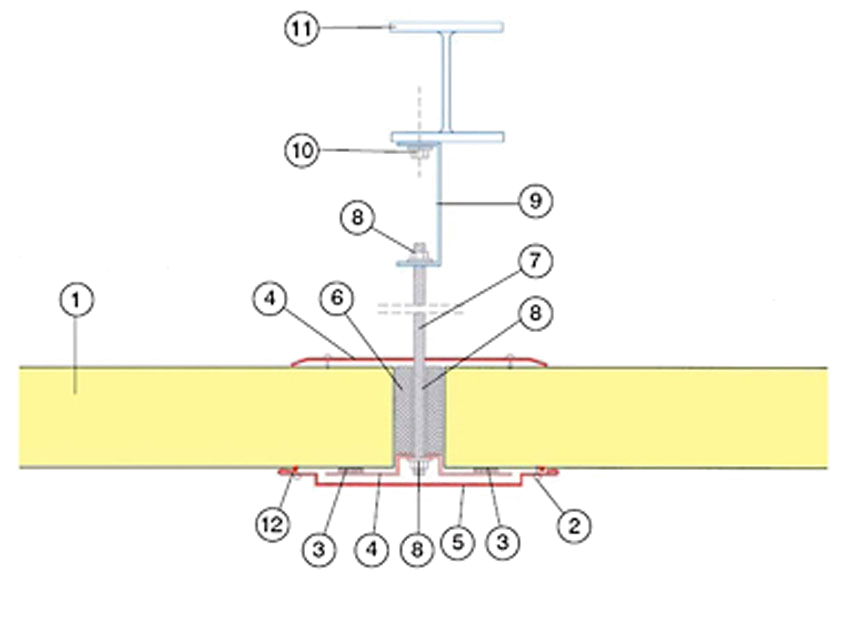

- 1. ECOPANEL FL

- 2. Rivet

- 3. Sealing tape

- 4. Supporting galvanized Ω profile

- 5. Omega coated steel flashing

- 6. Polyurethane injection

- 7. Teflon screw rod

- 8. Nut

- 9. Galvanized U profile

- 10. Screw

- 11. Truss

- 12. Silicone sealant

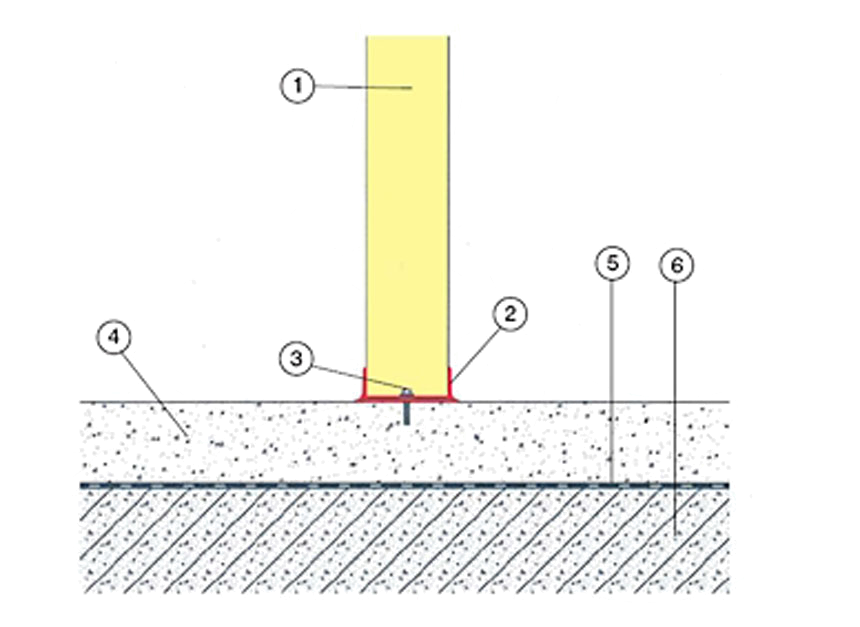

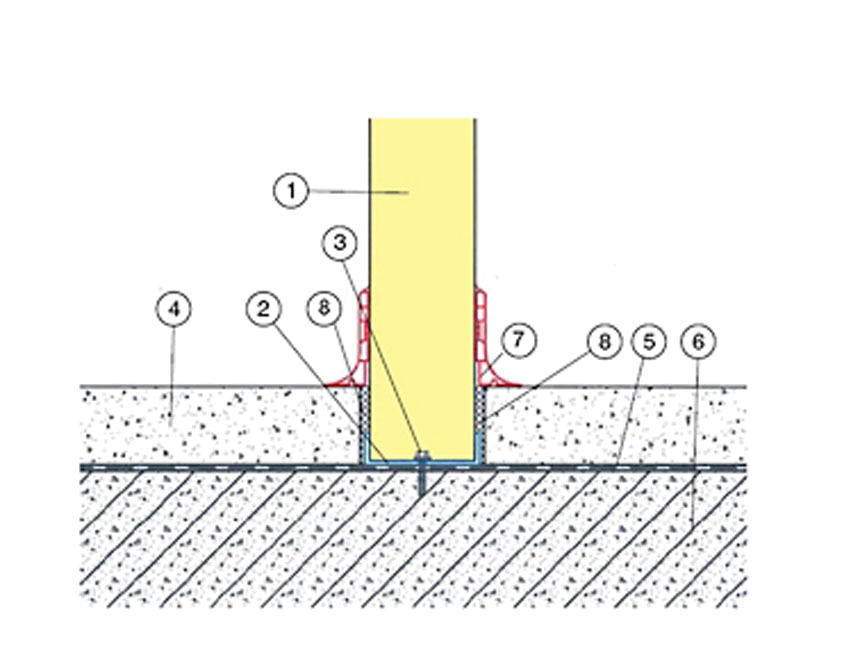

- 1. ECOPANEL FL

- 2. U channel sanitary profile

- 3. Pin and screw (M 8 in 600mm interval)

- 4. Finished floor

- 5. Vapour-seal

- 6. Concrete floor

- 1. ECOPANEL FL

- 2. U galvanized steel profile

- 3. Pin and screw (M 8 in 600mm interval)

- 4. Finished floor

- 5. Vapour- seal

- 6. Concrete floor

- 7. Sanitary skirt

- 8. Thermal insulation

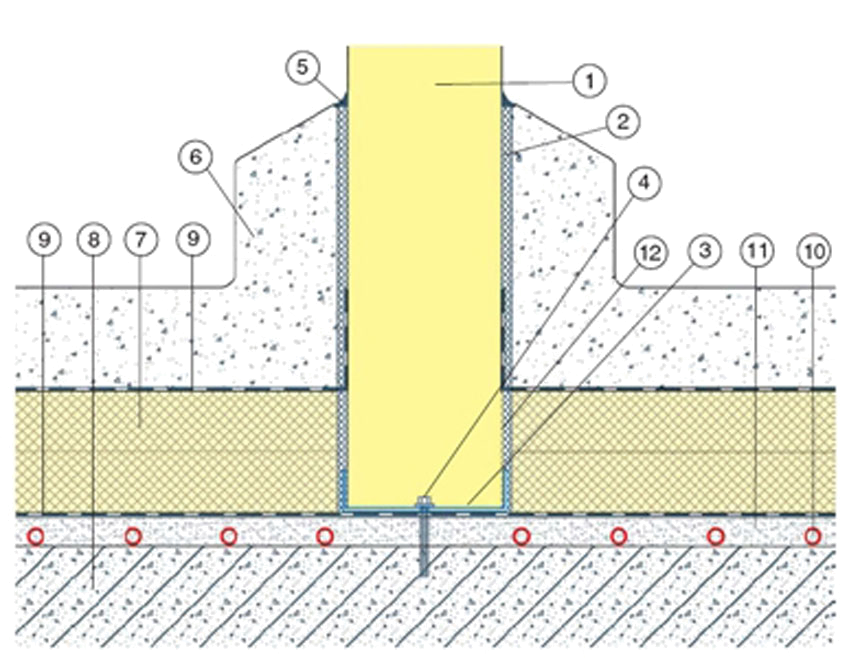

- 1. ECOPANEL FL

- 2. Thermal insulation

- 3. Galvanized steel U profile

- 4. Pin and screw (M 8 in 600mm interval)

- 5. Silicone joint

- 6. Finished floor

- 7. Floor insulation

- 8. Concrete floor (heated or ventilated)

- 9. Vapour-seal

- 10. Heater elements

- 11. Sand cement screed

- 12. Thermal break (Steel sheet cutting)

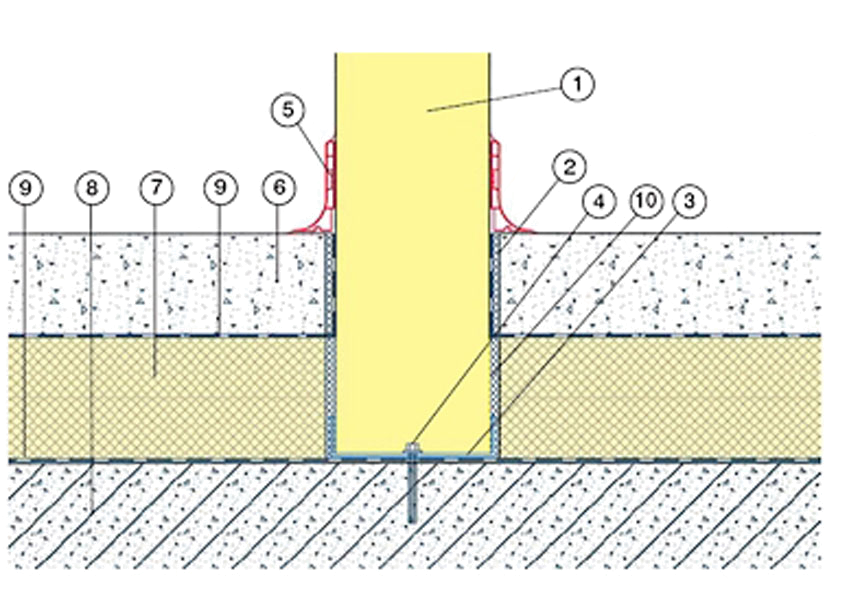

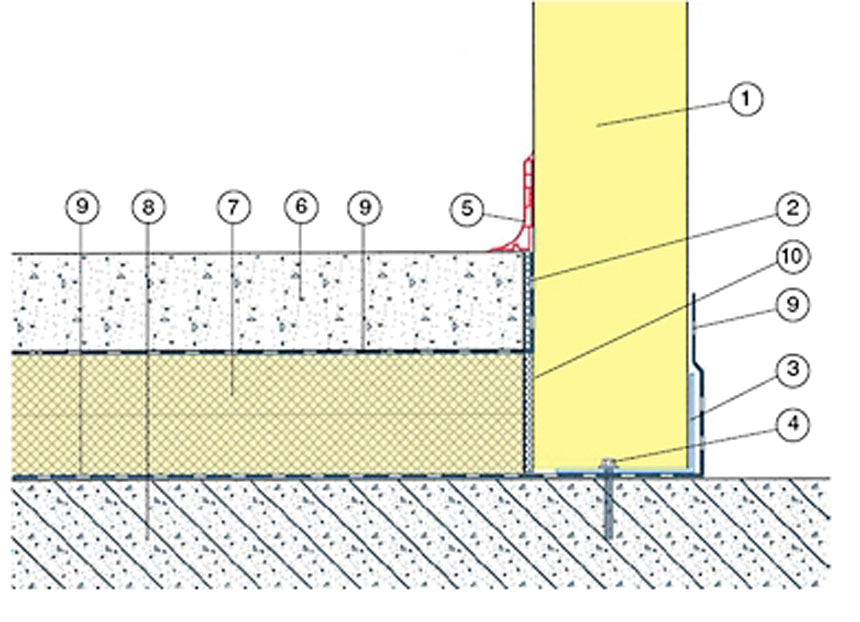

- 1. ECOPANEL FL

- 2. Thermal insulation

- 3. Galvanized steel U profile

- 4. Pin and screw (M 8 in 600mm interval)

- 5. Sanitary skirt

- 6. Finished floor

- 7. Floor insulation

- 8. Concrete floor (healed or ventilated)

- 9. Vapour-seal

- 10. Thermal break (Steel sheet cutting)

- 1. ECOPANEL FL

- 2. Thermal insulation

- 3. Galvanized steel angle profile

- 4. Pin and screw (M 8 in 600 mm interval)

- 5. Silicone sealant

- 6. Finished floor

- 7. Floor insulation

- 8. Concrete floor (heated or ventilated)

- 9. Vapour-seal

- 10. Heater elements

- 11. Sand cement screed

- 12. Thermal break (Steel sheet cutting)

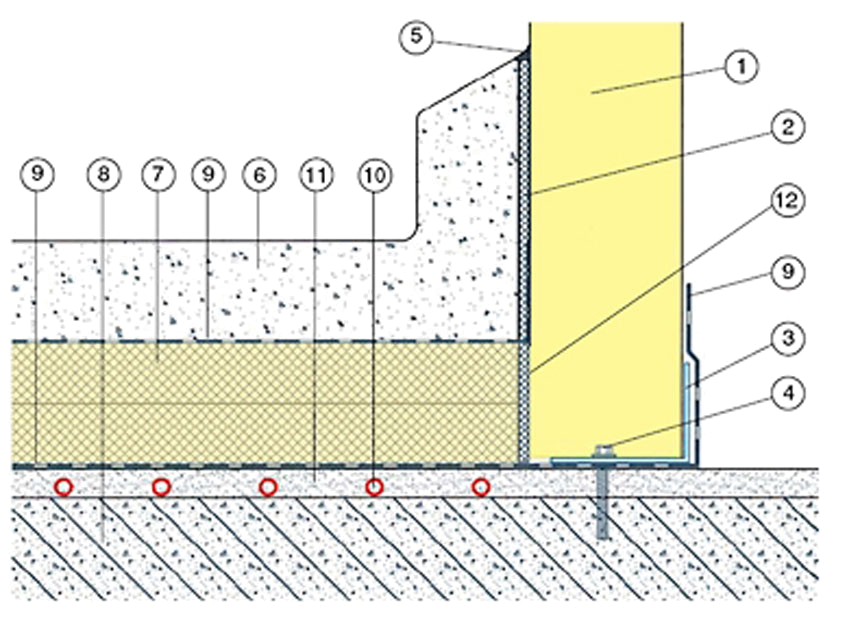

- 1. ECOPANEL FL

- 2. Thermal insulation

- 3. Galvanized steel angle profile

- 4. Pin and screw (M 8 in 600mm interval)

- 5. Sanitary skirt

- 6. Finished floor

- 7. Floor insulation

- 8. Concrete floor (healed or ventilated)

- 9. Vapour-seal

- 10. Thermal break (Steel sheet cutting)